Elon Musk discusses Falcon 9 upgrades

Musk: "This is SpaceX 9th launch of 2018. By this time last year, we had only done five missions. We are on track to be double our launch rate from last year. Falcon 9 was the most-launched rocket of any company in 2017.

"The goal with Block 5: this is the arguably Falcon 9 Version Six. This will be the last major version of Falcon 9 before BFR. There might be small improvements to assist manufacturabality. But those will be minor changes: 6.01, 6.02.

"This will be the mainstay of SpaceX. We expect 300 flights of Falcon 9 Block 5 before retirement. One of the biggest goals os Block 5 is the ease of reusability. We are planning 10 flights with no refurbishment between flight. We have to re-load propellant. There will be moderate scheduled maintenance after 10 flights. Each core should be able to fly 100 times before being retired.

"We intend to demonstrate two orbital launches of the same core no later than late next year. That will be truly remarkable. You have to transport the rocket back to the launch site, re-mount a new payload and fuel the rocket.

"We will meet all of the NASA requirements for reliability as well as meet all of the USAF's requirements for extreme reliability. Our intent is for this to be the most reliable rocket ever built.

"In terms of performance: The Merlin engine thrust has been increased by 8%. There might be more room there - perhaps up to 10%. The efficiency has increased without adding any mass to the engine. It was already the best thrust to mass ratio and Block 5 has gotten better.

"We have new thermal protection technology. The black interstage, raceways, and landing legs. The thermal protection was developed at SpaceX. It is very hydrophibic: it will not trap water. I like the asesthetics of the black more. It is like the Falcon 1 rocket. Looks are a minor factor, but I like for nostalgic reasons, the return to the black interstage.

"The Octaweb at the base of the rocket: It protects each engine from the neighboring engines. It is made of a much higher strength material. The strength is dramatically better. It also has better thermal protection in case of an engine fire.

"Landing legs: There is no scallops on the end of the leg. We've brought that feature on to the leg itself. Deploying landing gear and retracting will now be ve easy, while it used to take a few hours to stow the landing gear.

"Titanium Grid fins will replace the old grid fins. We think it is the largest titanium forging in the world. It can withstand 1000 degrees centigrade without any problems.

"About a reusable upper stage: We are gathering data on the upper stage during re-entry. We are learning more and more about when the second stage breaks up. It is like a ball of plasma. You can only broadcast diagonally backwards, so we have to communicate with the Iridium constellation. We will be adding more and more thermal protection to the upper stage to figure out the least amount of mass we can add to the upper stage and have it be recoverable. We have to make sure not to add any risk to the ascent phase of flight. That will be very exciting. The upper stage is about 20% of the cost. IF we were able to re-use all elements of the rocket, we could reduce the cost per launch by an order of magnitude. The propellant only costs $380-$400K per launch. Ocean Recovery adds a few million dollars. We could get the cost down to $5-$6 Million."

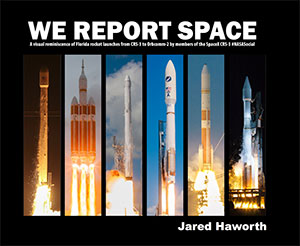

Stunning, full color photo book covering every east coast launch spanning 2014-2015, including the first-ever powered landing of a SpaceX Falcon 9 rocket.

More Info